Launchpad - Mechanized lift

Par olcabour le vendredi, 23 décembre 2011, 11:31 - Launchpad - Lien permanent

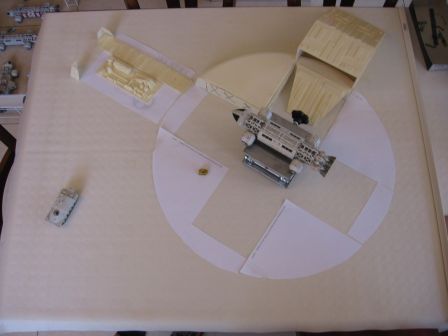

I really wanted to mechanize the platform (an old childhood dream) and could not find an easy solution, which did not require me to become an electronician apprentice. On the advice of Alexandre Dumas, I made the acquisition of a small laboratory support (LabJack). http://www.crscientific.com/labjacks.html

The minimum deflection of the support is 6.5 cm (the max being +30cm) and as a platform measuring ~5.5 cm high, if I want to have a run of 10 cm for the orange elevator, the dio will therefore be based on a box of 11 cm minimum height. The top plate of the LabJack is simply fixed with screws, so I may remove it and replace it with L aluminum strips (these strips will be reinforcements of the orange platform).

The same goes for the feet (they are screwed), so the labjack can be easily fixed on a board inside the dio box.

A little test

Finally, that will do it, but dio is getting a good fifteen cm thick in this story !

It remains me to solve the problem of the engine of the elevator, which is now limited to the engine the LabJack, and therefore its central wheel.

After looking again for a while on the side of the electronics with stepper motors for example, Jean-Marc Deschamps arrived to the rescue (as Zorro on his big black horse:-D) with an easy solution : an electric screwdriver connected to the labjack with an flexible mandrel extension

A final detail remains to be settled: build stops in this mechanism to prevent the elevator from exceeding the top of the platform, without damaging it by the way, and always without electronic's. The idea is to block the mechanism just enough time to remove the finger from the trigger of the screwdriver.

For now, I only see two solutions:

- use a tube to plug in the central screw and block it

- make a hole in the central screw to insert a stop