Battlestar Galactica - Half studio scale - Display stand

Par olcabour le mercredi, 27 août 2014, 23:59 - Battlestar Galactica 37 - Lien permanent

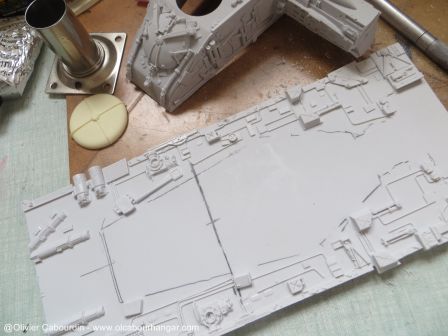

After much research, I found a simple way to install a support strut in the main body.

I'll use a 3cm diameter metal table leg, screwed on a medium plate, itself screwed to the central part of the ship.

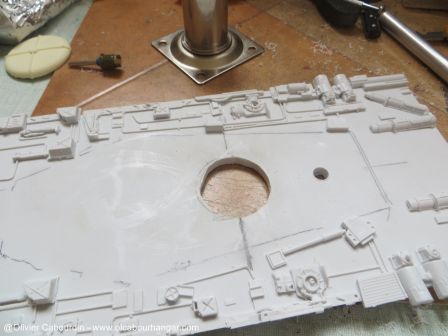

The foot is cut to stay within the model. Via copper tubing and the other part of the table leg, it will rest on the foot of an old office armchair.

It will be the support for display on our stand, there will certainly be other less high and fixed.

The power wires will run inside the support, so a hole is made in the foot to let it go out (so it will be invisible in the model).

I will made some other support options to vary the displaying ways :

- From above, here I use an hardware kit for bedstead.

- From each side, via steel square tubes. This will require much more work: hollow all along the resin part that connects them (belly cross), drill and adjust accordingly the hangars.

I will fill the hole with resin later.

With this metal bar in the middle, the inside of hangars will be cut in half, so will be the future detailled interior (which, I hope, should not be seen in the end).

All this means that I will also have to provide three more power paths.

To strengthen the big resin parts and prevent them from bending under their own weight in the future, I prepared wood reinforcements (with 1 cm thick medium).

Notches in the medium are made to let the optical fibers run there later.

The head is the part that asks me the most concern. Here the resin is thin. On the upper part as the bottom one, the edges are very thin and in my opinion not thick enough to hold the weight of the bottom piece over the long term. So I think to screw the parts together, which will require a bit of preparation.

Meanwhile, the upper is reinforced with an aluminum U-channel and a block of medium wood.