Battlestar Galactica - Half studio scale - Parts cleaning

Par olcabour le lundi, 25 août 2014, 22:43 - Battlestar Galactica 37 - Lien permanent

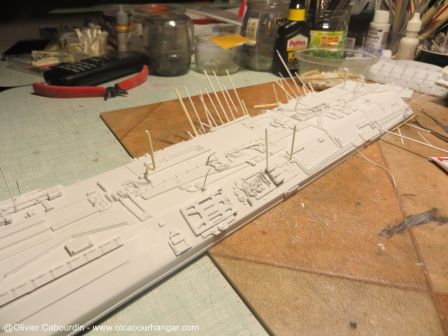

I marked all the window locations and drill then with (0.75mm diameter) for the optical fibers.

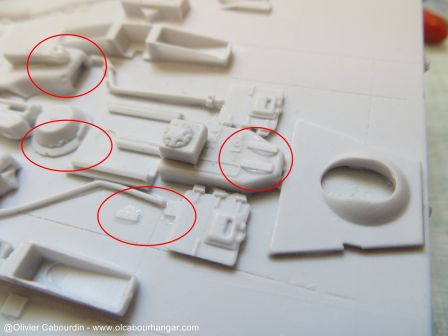

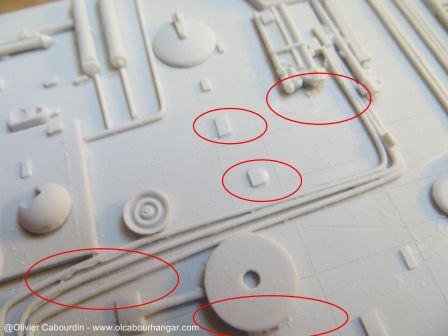

Parts preparation is laborious. Because there is finally a lot of tiny molding flaws, and bubbles hidden in the details.

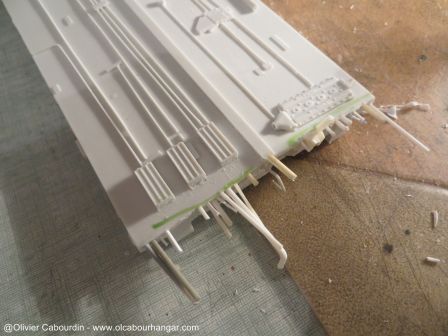

Bubbles are filled with my shaggy hedgehog method ! So with the rods glued into each hole with cyano.

Sometimes I had to simply replace a detail too damaged with a tank part, or an Evergreen strip.

Long weeks were needed to reach the end of this step.

example before / after (an hour later!)

To take my mind off of this cleaning job, I get forward slowly on other works : internal bracing and support means ...