- Yellow lights boxes

On each side of the head and the motor module, there are small boxes with bright yellow 6 points each. The parts supplied are a little too big and different between the front and rear. So I've modified or replaced, and then glued to drill the holes for the fibers.

Front ones

Back

- remaining gaps

I filled few gaps between the large parts:

Here on the neck

and the engine module.

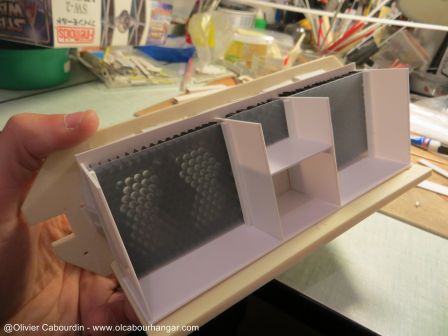

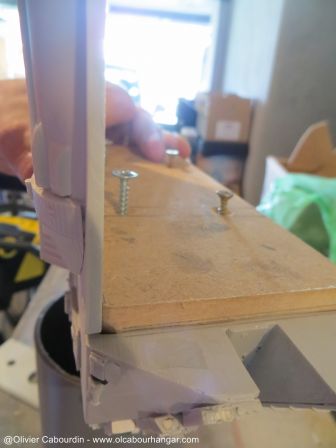

-- Last complete dry test before lights installation and hangar detailling.

The usefull thing of this assembly with screws at this step is that everything can be dismantled easily.

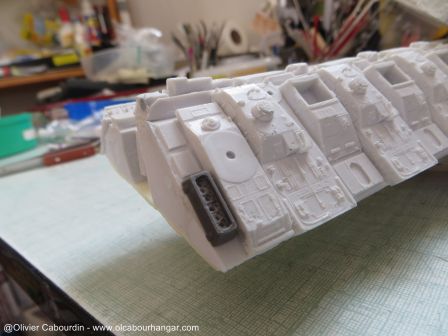

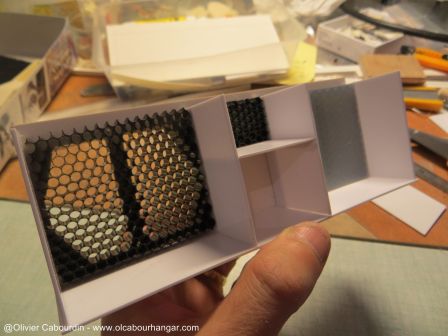

- Launch tubes and replacement hangars details

Viper Launch tubes are installed. A small strip of plastic card brings it the right level

The resin plates replaced the ones on the kit. There are 3 on the right hangar, two on the left one, not symmetrically placed as on the studio model.