Moebius Viper mk7 - Socket installed

Par olcabour le lundi, 10 mars 2014, 21:59 - Moebius Viper mk7 - Lien permanent

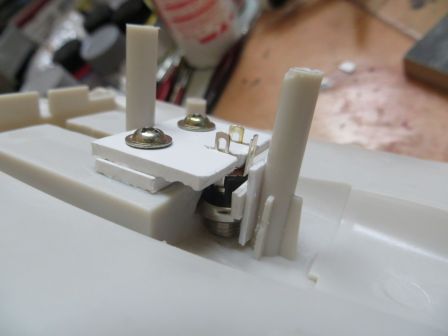

To hold the socket, I help myself with the studs and rear landing gear wells. The middle pin was removed to get some space, then I started to sand in the well walls.

To hold the connector, I blocked it with a plastic square, in which 2 slots are made to free the socket metal tabs.

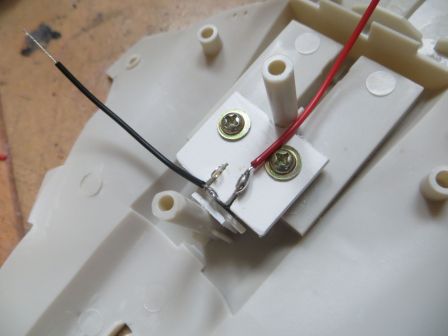

This plate is glued and reinforced with 2 screws. To have more material for the screws, 2 small wooden blocks are installed with hot glue in the landing gear wells.

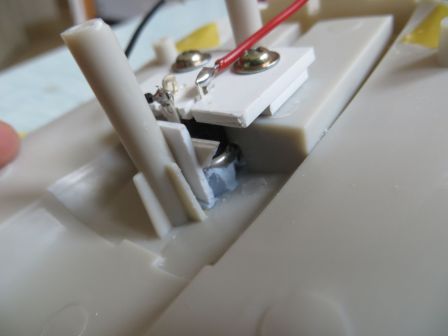

2 part modeling glue closes the openings around the socket.

Hatches and intakes are glued. The hole of the original support is clogged with plastic card, reinforced from behind again by a mixture of cyano and resin dust.