Space1999 tanks - Cleaning parts

Par olcabour le mardi, 21 mai 2013, 22:29 - Tanks - Lien permanent

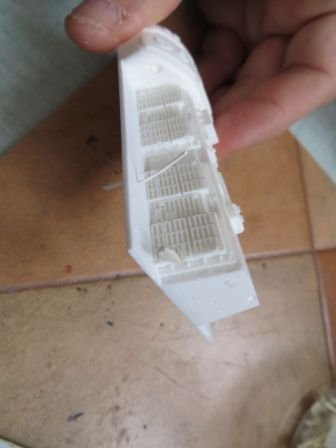

There are some bubbles on much parts, but the problem is that their number increased about three times because of underlying ones, appearing after the first cleaning works. So I apply my hedgehog method :) : they are filled with plastic rods and superglue. It is much faster and efficient than putty.

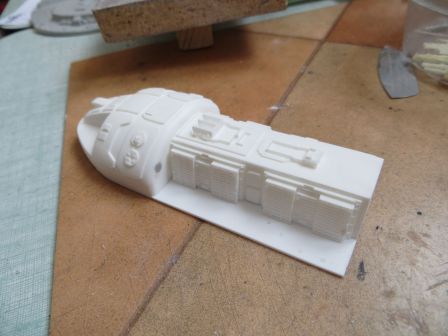

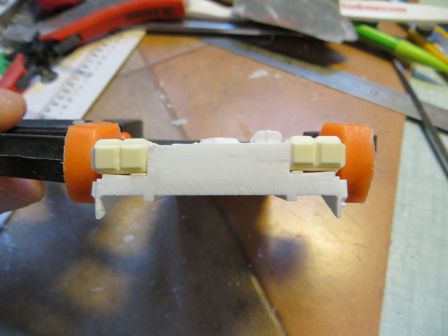

Some wedges are needed to align the trunk parts on the back page of the Model F

The front part of the model F was slightly bent, it was corrected after a quick bath in hot water.

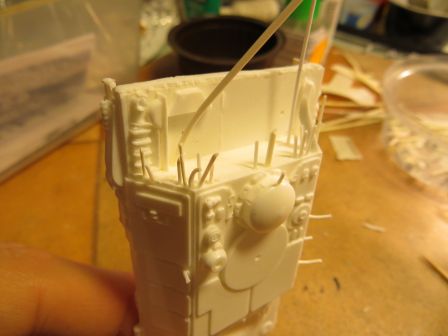

At the rear of the model H, there is a so large bubble in the can that it is better to completely replace it. It is redone with some tree part from a plastic kit, the claddings are simply made with Tamiya tape.

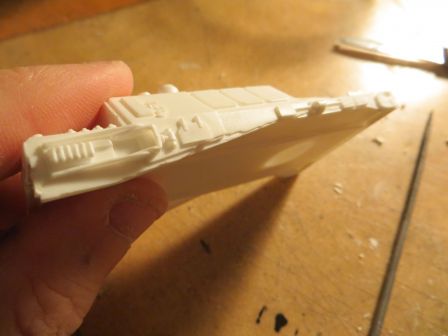

Some grooved part are very thin on the guns, and I had "fun" cleaning then and redone some with some spare flash material laying on the workbench.

The barrel of the model F is wrong and need to be sanded to the correct shape.

On the underbody, are often stems that also did not survived the casting. It did not matter because they inspired me very little confidence and would surely not had supported the track tension. So I cut everything, and I replace them with metal rods.

Thermoformed transparent parts (cockpit domes) are prepared. We can see that one of them had no chance and see decked out with a fold that I had not seen at the opening of boxes. Not having the time to make a new master, I use it as is. It will glued with the repositionable Microscale glue, so I will be able to easily remove and change it later.